|

A 7-Step Plan to Prevent Atypical Newcastle Disease

Producers and veterinarians search for "atypical Newcastle disease prevention" when performance declines suggest ND but outbreaks don’t look classical. This guide focuses on the problem—why atypical ND evades standard programs—and delivers a practical, evidence‑based prevention plan. A residue‑free, herbal antiviral tool is introduced only where it directly solves a field pain point. Why atypical Newcastle disease is hard to prevent

Many managers picture Newcastle disease as dramatic, with high mortality, neurological signs, and greenish diarrhea. Atypical Newcastle disease often plays out differently. Signs can be subtle or mixed: a chronic respiratory picture, patchy growth, small and persistent egg dips, and sporadic mortality. Co‑infections (for example, E. coli) may cloud the diagnosis. Because the clinical picture is muted and overlaps with other conditions, atypical ND can erode feed efficiency, livability, and egg output for weeks before it’s recognized. Prevention must therefore close small but cumulative gaps in surveillance, vaccination integrity, biosecurity, water delivery, and stress control. Where prevention programs usually fail

Timing: Boosters misaligned with production curves or local challenge pressure; immune suppression around heat stress, feed changes, or mycotoxin exposure. Biosecurity drift: Lapses in people and equipment flow, inconsistent crate/vehicle hygiene, and weak litter management, especially during catching/thinning. Waterline issues: Biofilms and variable water quality reduce vaccine performance and aid pathogen persistence. Delayed sampling: Atypical signs delay PCR/serology, extending the loss period.

A 7‑step prevention plan for atypical Newcastle diseaseStep 1: Build early surveillance into daily routinesDefine high‑risk windows: placement, days 3–7 post‑vaccination, thinning/catching, sudden weather shifts, feed transitions, and nearby farm alerts. Track sensitive indicators: cough/sneeze index, daily water intake per 1,000 birds, feed intake deviations, egg production and shell quality, and any uptick in condemnations.

Step 2: Protect vaccine viability and immune responseVaccine integrity: Keep cold chain intact to the barn; reconstitute with clean, dechlorinated water; avoid metal containers; follow time‑to‑use directions precisely. Schedule to challenge: Ensure broilers are primed and boosted per veterinarian guidance; time layer/breeder boosters ahead of anticipated challenge or production peaks. Stabilize birds: Around vaccination windows, control heat and stocking density; ensure electrolyte balance and good gut condition to support antibody development.

Step 3: Close biosecurity gaps that atypical ND exploitsEntry control and flow: One controlled entrance with hand wash and boot dips; move from youngest to oldest flocks; assign tools per house; maintain visitor logs. Crates, vehicles, and equipment: Standardize washing and disinfection between farms and plant; validate contact time and concentration. Turnaround: Dry clean dust and organic matter, wash, disinfect, and allow drying time; where possible, include some downtime before restocking. Ventilation: Tune fans and inlets before seasonal changes; monitor temperature and humidity swings that depress immunity and favor spread.

Step 4: Get water quality and delivery rightPotability and pH: Test source water regularly; keep microbial load in check; manage minerals that can affect additive efficacy. Biofilm control: Establish routine waterline cleaning that physically removes biofilms; select agents compatible with your system.

Step 5: Reduce co‑infection pressure and secondary lossLitter and density: Manage moisture to limit bacterial bloom and aerosolized dust; adjust density and airflow to the birds’ level. Confirm and target: Base antibiotic use on confirmed bacterial issues; follow label and withdrawal guidance strictly—especially in layers. Support recovery quickly: Faster fever reduction and return to feed/water intake cut the window where opportunists proliferate.

Step 6: Train, audit, and standardize

Micro‑training: Short, frequent refreshers on entry protocol, vaccine mixing, and waterline hygiene; place visual SOPs in barns. Triggers and responses: Define thresholds (for example, a specific % drop in water intake) that trigger sampling and supportive measures. Records that matter: Log vaccine lots, mixing times, house conditions, and daily performance; review weekly to identify patterns.

Step 7: Add a residue‑free antiviral layer at critical timesAtypical ND often exploits stress windows. Alongside vaccination and biosecurity, many operations add a residue‑free antiviral support layer to stabilize birds and improve vaccine outcomes—without creating withdrawal constraints. How a herbal antiviral layer fits

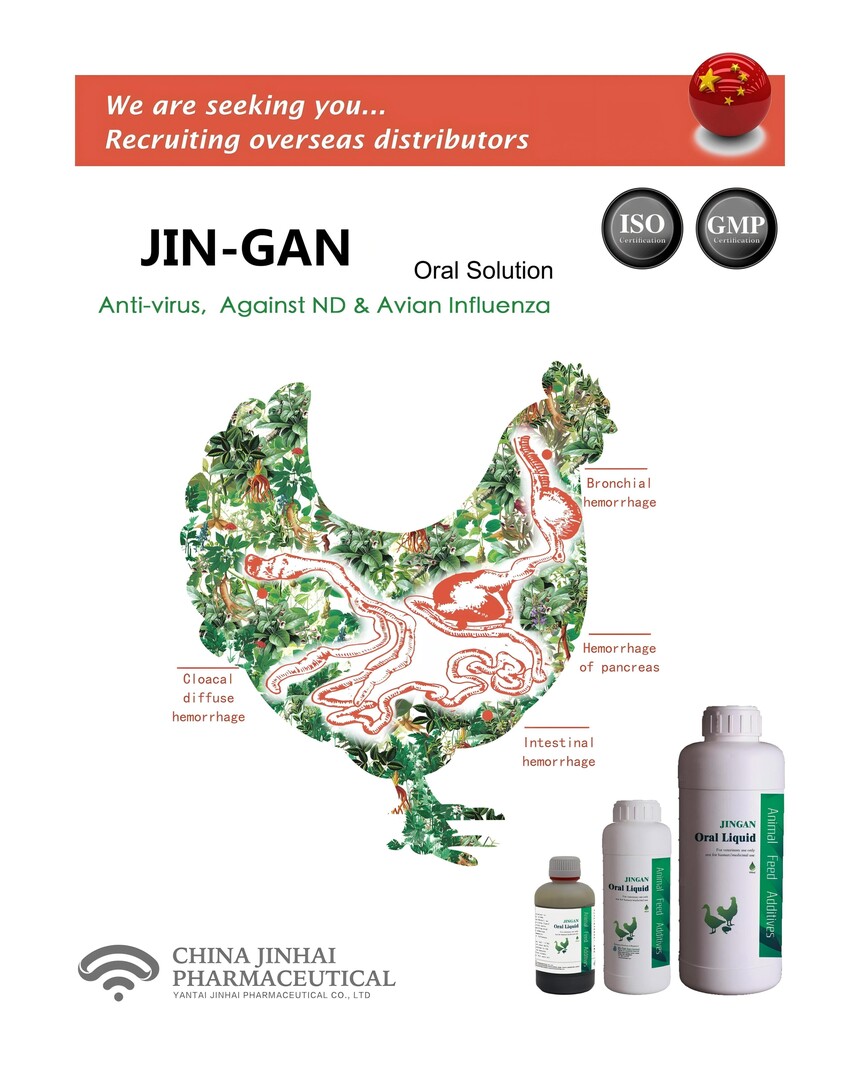

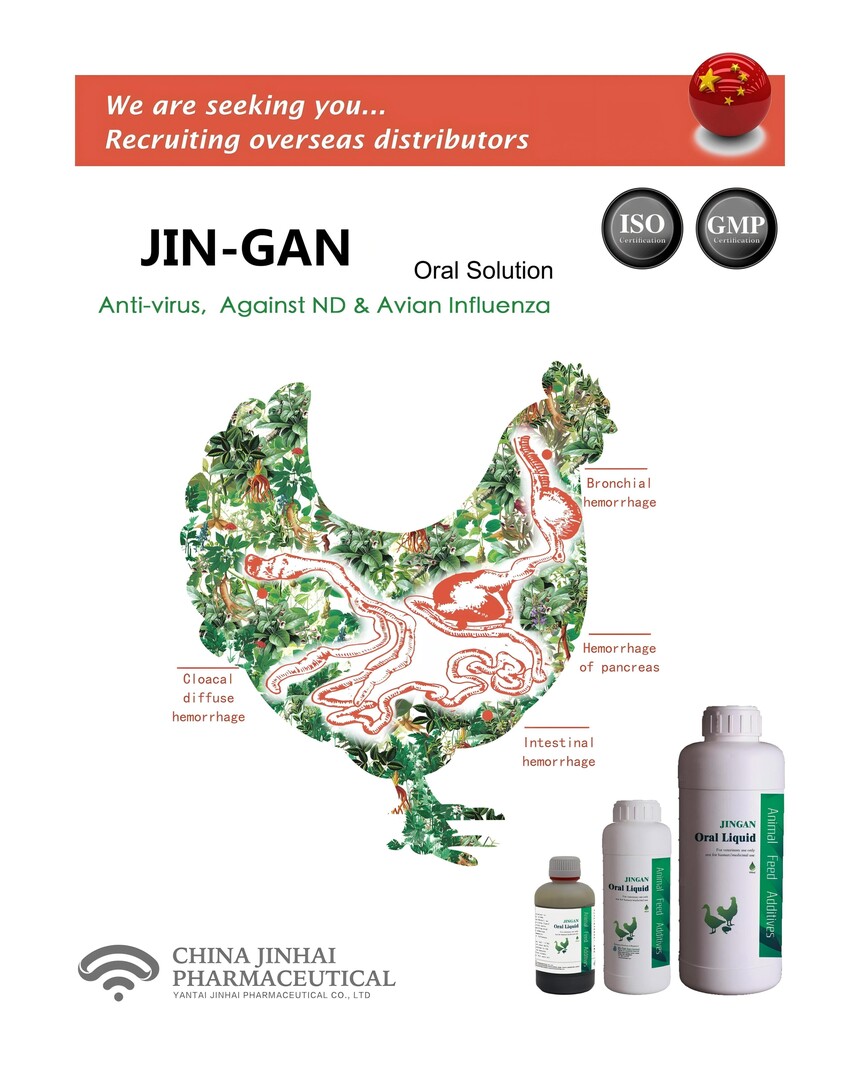

JIN‑GAN liquid (AntiViral Defense) from Yantai Jinhai Pharmaceutical is a GMP‑certified herbal antiviral based on Honeysuckle, Scutellaria, and Forsythia extracts, standardized by HPLC for consistency. It provides broad‑spectrum activity against ND and Avian Influenza (H9) with zero residue. Field use is associated with rapid fever reduction and restoration of feed intake and productivity. When co‑administered with vaccines, antibody titers are significantly enhanced, improving overall immune protection. JIN‑GAN can also be combined with antibiotics under veterinary guidance to manage secondary bacterial infections. Practical deployment ideasPre‑/post‑vaccination: Use a short course around live vaccine events to help stabilize birds and support serological response. Suspected atypical ND: When early indicators trend negative, a supportive antiviral layer can limit productivity loss while tests are pending and containment steps are implemented. Layers and residue compliance: Zero residue and no withdrawal align with egg safety requirements while sustaining lay under pressure.

Aligning prevention to production typesBroilers: Emphasize surveillance, waterline hygiene, and rapid supportive care to protect FCR and uniformity. Layers: Focus on vaccine take quality, residue‑free support, and stabilizing daily egg output and shell quality during stress. Breeders: Prioritize strict biosecurity at placement and transfer, plus immune support that protects hatchability and chick quality.

Measuring successSerology: Improved and more uniform antibody titers post‑vaccination indicate strengthened protection. Intake and performance: Faster normalization of water/feed intake and return to target growth or lay confirms effectiveness. Intervention profile: Reduced need for rescue antibiotics while maintaining compliance signals a stronger, more resilient program.

Key takeawaysAtypical Newcastle disease prevention is about execution across multiple small levers—surveillance, vaccine integrity, biosecurity, water management, and stress control. A residue‑free herbal antiviral layer such as JIN‑GAN liquid fits naturally into these levers, supporting vaccine performance, accelerating recovery, and avoiding residue constraints. Start with two actions this week—audit vaccine mixing and clean waterlines—then schedule the remaining steps. Monitor, adjust, and compound gains flock by flock.

Note on classical Newcastle disease responseClassical (typical) Newcastle disease is acute, severe, and fast‑moving. In many jurisdictions, confirmed cases are handled by immediate culling and strict containment under veterinary and regulatory direction. Prevention remains critical, but once detected, rapid depopulation is the norm to protect neighboring flocks and regional trade.

|

|